In this modern world, we’ve invented many technologies to make our lives easier and the air compressor is one of them. An air compressor is a common thing that we use. Often, people wonder how does air compressors work? They want to know the working method of this amazing technology.

So, we decided to write about the work method of an air compressor. If you’re eagerly waiting for knowing this, then don’t waste time and jump into the discussion.

What Is The Air Compressor?

The air compressor is a special twofold process in which the air pressure rises while the volume drops.

How Does An Air Compressor Work?

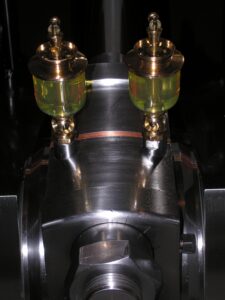

To know the working method of an air compressor, you need to get familiar with its parts first. Most of the air compressors on the market are accomplished with reciprocating piston technology. So, we’re going to learn about the reciprocating piston technology-based air compressor. This type of air compressor has the following main parts-

- Crankshaft;

- Connecting Rod;

- Cylinder;

- Piston;

- Valve Head;

Piston Functionality

The air compressor functionality is based on a very simple principle. When the pressure increases, the air is compressed and the volume decreases. This is the common and easiest way to achieve with a reciprocating piston. To create air pressure, there are air compressors that employ rotating impellers.

You have known the name of the parts earlier. These parts work together to make the entire mechanism work. And to make the mechanism work, you need power. With the power, these parts work together and the air compressor works.

Air compressors are mainly run by the power of gas or electricity. It depends on the models. In every air compressor, there is a valve head at the top of the cylinder. This valve head contains 2 different parts- the inlet and the discharge valve. These are mainly metal flaps. The inlet and the discharge valve are located on the top of the valve plate and open and close mainly according to needs.

When the piston moves down inside the cylinder, the whole function starts working. With the piston moving in the space above the piston, a vacuum is created there. Here is the clever trick. When the vacuum is created, it also makes a difference between the air pressure inside the cylinder and the atmospheric air pressure.

As a result, the atmospheric air opens the inlet valve and enters the area where the vacuum used to be. And when the atmospheric air enters the vacuum zone (inside the cylinder), the piston goes up and compresses that atmospheric air.

In the meantime, the inlet valve closes and the discharge valve of the compressor opens and the compressed air goes to the tank. The compressed air is stored inside the tank by increasing the pressure. You may have noticed, that there is a tank with every air compressor. The air compressor compresses the air and stores it in the tank. Compressed air is used to power up various air tools when they need it.

Dual Piston Based Air Compressor

We just discussed the basic working method of a single-piston-based air compressor. There are variations to the approach of the air compressor to make it more powerful. So, the dual piston-based air compressor was made.

Look, the basic working principle is the same. Dual piston-based air compressors are very common now to enhance the ability of the compressor. The only difference is there are two strokes per revolution in a dual piston-based compressor. The rest of the working method is the same.

In the dual piston compressor, there is a two-stage compression system that uses one piston to pump the air into a second cylinder. This type of air compressor compresses the air two times to create greater pressure. Simply, you get compressed air in a single-piston compressor and get more compressed air in the dual piston compressor.

But remember, storing too much compressed air in the tank may create an unwanted situation. The tank may explode because of too much-compressed air. That’s why the compressor has a switch that cuts power to the motor when the pressure reaches the limit inside the tank. The inside pressure limit is usually around 125 PSI. So, when the limit is reached, the switch cut the power to prevent the tank from exploding.

But different air tool needs different types of air pressure. To make sure the right pressure, there is a regulator as well to measure the air pressure and control that. In addition, there is an un-loader safety valve that reduces the air pressure inside the tank when the compressor stays idle. This is a safety system to keep the compressor safe from any unwanted occurrences.

Additional Report Lubrication

To know the working method of an air compressor completely, you should know about the way how it is lubricated. You may have heard the terms like “Oil-Lubricated Pump” or “Oil-Free Pump”. The Oil-lubricated pump has an oil bath that lubricates the inside wall and bearing of the cylinder. The oil and the air are kept separate by the piston rings. But this does not works 100%. So you may get air with mixing oil and that can be problematic.

On the other hand, the Oil-free pump has a permanently lubricated bearing. It does not require a lubrication bath like an Oil-lubricated pump. Actually, many power tools need to be lubricated so that isn’t any problem to use the Oil-lubricated pump unless you’re using power tools for woodworking or painting. An oil-lubricated pump may mess with the finish or painting and woodwork.

Final Verdict

The working method of an air compressor is quite easy and simple. We hope we explained it clearly. Actually, an air compressor looks like a complex mechanism. But in reality, it’s really simple and works depending on some simple and easy principles.